Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔥 Bond like a boss—fast, tough, and professional-grade! 💪

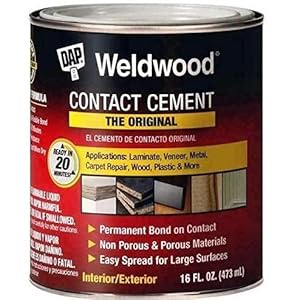

DAP 271 Weldwood Original Contact Cement is a premium, neoprene-based adhesive designed for professional use. It dries quickly in 15-20 minutes, forms a durable, water- and heat-resistant bond, and works seamlessly on a variety of materials including wood, leather, rubber, and plastic laminates. With over 15 years of trusted performance and a high customer rating, it’s the go-to choice for demanding repair and woodworking projects.

| ASIN | B0006MXRY8 |

| Best Sellers Rank | #36,318 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #97 in Contact Cements |

| Brand | DAP |

| Brand Name | DAP |

| Color | TAN |

| Compatible Material | Plastic |

| Container Type | Bottle |

| Customer Reviews | 4.6 out of 5 stars 2,839 Reviews |

| Full Cure Time | 7 Days |

| Global Trade Identification Number | 00070798002715 |

| Included Components | DAP - 7079800271 - 16oz |

| Item Form | Liquid |

| Item Height | 5 inches |

| Item Package Quantity | 1 |

| Item Type Name | extension-ladders |

| Item Weight | 1.1 Pounds |

| Manufacturer | DAP |

| Material | polymer |

| Material Type | polymer |

| Model | 271 |

| Other Special Features of the Product | creates a strong durable bond |

| Special Feature | creates a strong durable bond |

| Specific Uses For Product | Repair, Woodworking |

| UPC | 182683003964 070798002715 795871576784 |

| Unit Count | 1.0 Count |

| Viscosity | High Viscosity |

| Volume | 473 Milliliters |

| Warranty Description | Limited Manufacturer |

| Water Resistance Level | Water Resistant |

T**R

Works great!

This is really good contact cement. It does what it is supposed to do.

U**A

Reliable for 15 years. One of the best contact cements !

As most people know, one of the best contact cements around. I have used it now for 15 years for leather applications. None has ever failed even through all climates. The durability is truly amazing. The price gas been going up ( as with everything else ) but at least here you get a premium product.

P**F

Works like it should

I use this co tact cement in a number of things, including plugging nail holes in tires. This glue is quality but the key is to let it dry on both surfaces. I used it to adhere canvas to plywood, upholstery fixes, tire punctures, art work attaching, even picture frame repair. Good stuff. Make sure the lid is secure between uses and it works a whole lot better when it’s warm outside.

T**K

Works well for veneer.

Had a couple of furniture rehabs I was doing that were mahogany. I needed to replace the veneer, and in my research saw that this was the best project to use. It came well sealed with clamps on top so there was no way this can was going to leak via transit. And as far as how well it works: it’s pretty awesome and sets up really fast. However the smell is simply awful. Very strong toxic smell, so absolutely wear a ventilator and use this product in a well ventilated space. I used it outside with two industrial fans running, and it still managed to sneak its stink inside my house. I had to leave the house for an hour, then air it out for a few minutes before the smell disappeared. So just a warning to anyone who is sensitive to chemicals. Be sure to clamp down your veneer or use heavy objects on top to keep the veneer flush while it fully cures, or you will get some bubbling. Nothing too bad, just a little annoying.

A**T

worked very well with adding veneer to our mid-century dresser

I got this Dap Weldwood Original Contact Cement 00271 to attach a paper-backed veneer to the top of our old American of Martinsville dresser that's been in my family since the 1960s that had gotten water damaged (from potted plants sitting on it). We think it was made in the 1950s. I tried refinishing the dresser top, but the thin veneer top had lifted, cracked, & chipped in one 5" area-there was just no way to fix it well enough to not look obvious, so I decided we should re-veneer the top. I wasn't sure what type of wood veneer it was, so I checked online for the different types of wood grain veneers and narrowed it down to Cherry that I would stain (it could also be walnut, but the cherry was a closer match unstained...and better price! LOL) I used this Weldwood Contact cement on a portion of a 2'x8' roll of paper-backed cherry veneer from Amazon. The dresser is just over 4' long & 21" deep so we've got extra for a future project [https://smile.amazon.com/Cherry-Veneer-Plain-Sliced-Sheet/dp/B009KN8INE/ref=sr_1_3?ie=UTF8&qid=1535399026&sr=8-3&keywords=cherry+veneer] After I filled in the missing veneer sections of the dresser with bondo & my husband sanded the top, we cut the veneer to size with a 1/2" extra edge all around & glued it to the dresser top with this Dap Weldwood Contact Cement (I rolled the glue onto both surfaces as seen in the first photo-the dresser top had a darker stain on it because I had first tried to repair it unsuccessfully). This Weldwood Contact Cement is strong stuff. Once it's stuck on...it's permanent. So when the contact cement was just "tacky" on both surfaces, we laid down square wood rods across the surface of the dresser and laid the veneer on top of that. Starting at one end, we pulled out each rod as we pressed the veneer onto the dresser. We let it rest for over a week with a lot weight on top, which included several heavy books & round weights evenly distributed. Note: you can use clamps, but for us, books and weights were definitely sufficient for this Weldwood Contact Cement-our clamps would have been difficult to evenly distribute pressure since the dresser is completely enclosed on the back & sides. Before placing the books, I covered the veneer with white butcher paper-wax side up to protect the surface from scratches, dirt, etc. After a week, we removed the weights & books-the veneer is perfectly flat!-trimmed off the edge & lightly sanded the top & edges to get ready to stain. To match the aged appearance of the dresser, I brushed one coat of Minwax Polyshades Mission Oak...left it on for about 5 minutes, then wiped it off (see photo attached). [https://smile.amazon.com/Minwax-613850444-PolyShades-Polyurethane-Mission/dp/B000QUFN4M/ref=sr_1_1_sspa?ie=UTF8&qid=1534540740&sr=8-1-spons&keywords=minwax+polyshades+mission+oak&psc=1] The last two photos are with three coats of Minwax Paste Finishing Wax.Minwax 785004444 Paste Finishing Wax, 1-Pound, Natural that we actually bought locally. [https://smile.amazon.com/Minwax-785004444-Finishing-1-Pound-Natural/dp/B000LNOZAW/ref=sr_1_1?ie=UTF8&qid=1535399564&sr=8-1&keywords=minwax+paste+finishing+wax]

S**O

The shrinking glu can and more expensive.

The same contact cement glue, but very small can. Everything is shrinking nowadays.

C**.

Great bond READ THE DIRECTIONS

If you want to glue something to something else this is your best bet. READ THE DIRECTIONS!! Don’t mess with this stuff it’s the real deal. The key is to wait the specified time for the two surfaces to become nice and tacky. Porous surfaces may need a few coats to build up a good varnish of tacky glue letting it dry a few minutes between coats. IF YOU FOLLOW THESE STEPS and work outside with proper PPE this stuff will glue just about anything together in a matter of seconds on contact and the final cured bond rivals epoxy for certain use cases. Works great for gluing dense foam to plastic or webbing material provided you build up a nice coat on the two surfaces.

A**D

Excellent for craft foam

I bought this to glue craft foam pieces for a costume, and it was an excellent choice! When testing it out, I tried joining two pieces of 2-mm-thick craft foam along the edge (i.e., only a 2-mm-wide strip of adhesive), and this resulted in an impressively strong joint--the foam would tear before the seam did. The glue needs to be applied to both pieces to be adhered together and allowed to dry for a short time before joining them together. The glue on each piece dries to a tacky layer of similar stickiness to a Post-It note, so it doesn't get stuck to anything but another glue-coated surface piece. However, the adhesion between two glue-coated pieces is immediate and strong--make sure you have everything positioned correctly before the two surfaces come in contact, because they probably won't come apart again! The joined sections remained flexible without any rigidity or brittleness resulting from the adhesive. The adhesive also did not loosen up or otherwise cause any issues when exposed to heat as I used a heat gun to shape the foam. For craft foam, I used two coats on each surface (letting the first coat dry before adding the next) due to the porosity--a single coat would soak in to the foam and not adhere securely. Non-porous substances like posterboard adhered well with only one coat. One caveat is to use cheap brushes to apply the cement. Despite soaking/cleaning my brushes in mineral spirits per the instructions, I was never able to fully get the glue out of the brush. After it dried, the brush was quite stiff--mineral spirits would soften the residue enough to use the brush for further gluing but never got it fully clean.

Trustpilot

2 months ago

1 month ago