Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔥 Mold Max 60: Mold with confidence, even when the heat is on!

Mold Max 60 is a premium high-heat resistant silicone rubber compound designed for industrial and scientific molding applications. It withstands temperatures up to 560°F (294°C), features low mixed viscosity for easy handling, and cures with very low linear shrinkage to ensure precise, durable molds. Ideal for professionals seeking reliable, fast-curing silicone molds that maintain integrity under extreme conditions.

| ASIN | B09MJPZH22 |

| Best Sellers Rank | #79,317 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #133 in Silicone Adhesives |

| Brand | Smooth-On |

| Color | Yellow |

| Customer Reviews | 4.6 4.6 out of 5 stars (386) |

| Date First Available | November 30, 2021 |

| Full Cure Time | 24 Hours |

| Item Form | Liquid |

| Item Package Quantity | 1 |

| Item Volume | 1 Gallons |

| Item Weight | 11 pounds |

| Item model number | Mold Max 60 |

| Manufacturer | Smooth-On, Inc. |

| Material | Metal, Rubber, Silicone, Tin |

| Number of Pieces | 1 |

| Package Information | Pail |

| Tensile Strength | 398 Pounds Per Square Inch |

| UPC | 751635273610 |

| Viscosity | Low |

| Viscosity Level | Low |

| Water Resistance Level | Not Water Resistant |

R**T

Great stuff for high heat applications!

Cures a lot faster than it says on the instructions which I didn’t mind. I’m using it to make some tin jigs and it works perfectly for that! Nice and easy to clamp because the silicone is very rigid. Maybe wear gloves when using because the red gets everywhere 😂. Very minimal bubble! Have made tons of jigs with it so far and it looks like it’s new still despite the crazy heat.

I**C

Cool works really well. High heat

This stuff was really cool to work with. Was able to make some really strong detailed molds, and pour pewder directly into them.

J**M

Casts pewter well and holds fine detail.

Very good for pewter casting, as long as you don't get the pewter too hot when you go to pour it. Holds the definition of the mold extremely well. Does need mold release with pewter. (I use a fine talc powder.)

D**N

Very useful, easy to learn

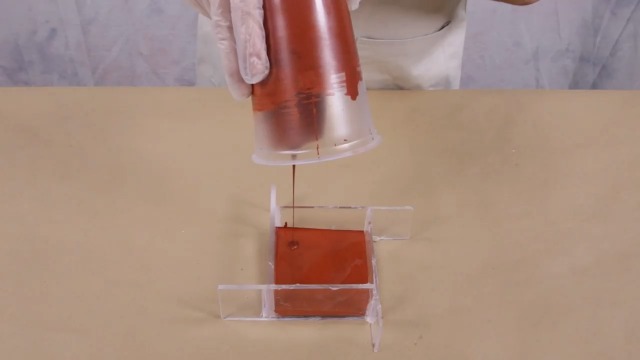

For first time silicone makers, these are the most important things to know: read the instructions, read them again, and then follow them. Make sure that you also have purchased Smooth-On's Universal Mold Release, as well as a gram scale and some disposable mixing utensils. As you can see from the image, the mold release made it so that I didn't even need to finish and smooth my mold parts. My first attempt successfully yielded a heating block boot for my MonoPrice Maker Ultimate (Wanhao Duplicator 6). It slid on easily and without tearing, and took well to heating. The included instructions tell you what you need to do for success, so I won't be outlining that. However, a tip that I can offer is to find a way to pour the B agent (the smaller bottle) without dribbling. If you know of a way to cut the seal into a pourable spout or have a topper that can fit over it, I recommend it. It splashes and gets everywhere. Do your math correctly, keep your scale handy, do this outside if possible, and you will be making great heat-resistant silicone parts in no time.

A**.

Works great for casting pewter. Using 10cc syringe to extract the blue liquid works best.

I bought the Mold Max 60 - Pint Unit. First time casting anything. I used R92 Pewter ingot and the mold handles the heat without seeming to be affected at all. Now about the product itself. The big container is unwieldy just because of how big the lid is and when pouring some out it will get all over the threads and hence on your gloves (wear gloves) and then on the lid and then on anything and everything you touch. And that stuff will still be wet the next day and beyond as it doesn't seem to dry out - ever. I used a 10cc syringe to get the blue liquid (small bottle) and that size syringe just fits through the mouth of the bottle. Two things I can say about the blue liquid is it splashes very easily so stir slowly and secondly, I don't think it takes as much as they say in the instructions as long as you stir well. Use flat bottom paper cups to mix it in so you can tear the remainder in the bottom out when it has cured - cut those little bits up and insert them into the next pour to essentially have no wasted mix.

J**B

Easiest Way to Cast Low Temp Metal, Tears Easily

For casting low temperature melting metals, it is hard to beat the convenience of this molding compound. I am making a large group of small figurines, was using zinc alloy and lost wax casting and it was a pain - too many ways to go wrong. Zinc has too high melting temp for this compound, so switched to pewter. I've been making molds and casting for over 40 years, mostly as part of my museum career, so I am very familiar with the silicones. What I can say about this material is it holds up to heat, but cured is very stiff. Molds needs to be designed with absolutely minimal undercut as eventually that spot will tear. You can buy red high temp silicon gasket caulk from an auto parts place to patch a tear, and limp through a few more casts. But really once it tears you need to remold. The good - takes amazing detail, reproduces probably more detail than can be captured in the metal. Convenient, and a well-designed mold yields dozens of cast parts. Much faster than lost wax without all the intermediate steps, as long as you are using something like pewter or tin. The bad - It is messy. This has to be the messiest molding compound I have ever used. It gets on everything. I've mixed countless thousands of batches of silicon molding compound without needing to use gloves. Not this stuff - it gets on everything, clings to it, and is then stained red forever. Part of the issue is that most silicon molding compounds change color slightly when the catalyst is mixed in. Not this stuff, so you have to mix very very thoroughly to ensure no uncured spots, but it's impossible to spot whether a drip is cured or not. Also, Smooth-On, in my experience, makes an art of giving you the precise, minimal amount of catalyst needed for the volume of silicon, and not one extra 1/2 drop. Usually that's ok if not a little annoying. But the catalyst for this compound is extremely non-viscous, so it tries to drip and run off the container while adding to the mix, so it is very easy to spill some, and then you're that much short of catalyst on the last batch you mix. I have had to resort to using a syringe minus the needle to measure out the catalyst just to ensure I have enough left at the end. That's why 4 stars - Smooth-On, quit being so cheap and give us an extra 1/2 ounce of catalyst. If you're paying $144 for a gallon of this stuff would it really hurt to give a tiny bit of extra catalyst?

S**K

Took high temp and allowed for great detail

I cast zinc, bismuth and minor other metal fine pieces at about 500f or below 600f and found this very easy to use. I used a silicone mold release for the second shell/half and it didn't work very well without a ton of effort and I sprayed it very thick. Next time I'll use a high viscosity liquid or almost solid soap/wax to most likely work much better. But it last many hours and only drawback is the time to produce the molds of which I was carefully at recommended full cure cycle to take for both halves at 24 hours per half or two days total. Not a big deal but noteworthy. I will be buying again PS my pieces were about 3/8 thick and my halves were each about 1/2 inch. Felt this was thrifty in my work as didn't use but a small amount. Tends do burn a bit but with zero degradation to detail or flexibility.

J**R

Muy buena calidad

Nice product

T**T

worked well was able to mould a lead keel bulb for a model yacht easy to use

A**R

While it did not appear that much of the product was lost, the lid did come loose in shipping, this could be problematic for others, especially where more product might be lost.

G**T

easy to use .

A**R

price marked up. product came looking opened already, spill and smear marks everywhere on instructions and bottles. the brand and product itself are great, made lead casting molds with perfect detail.

Trustpilot

2 months ago

3 days ago