⚡ Cut smarter, not harder — the pro’s choice for flawless aluminum slicing!

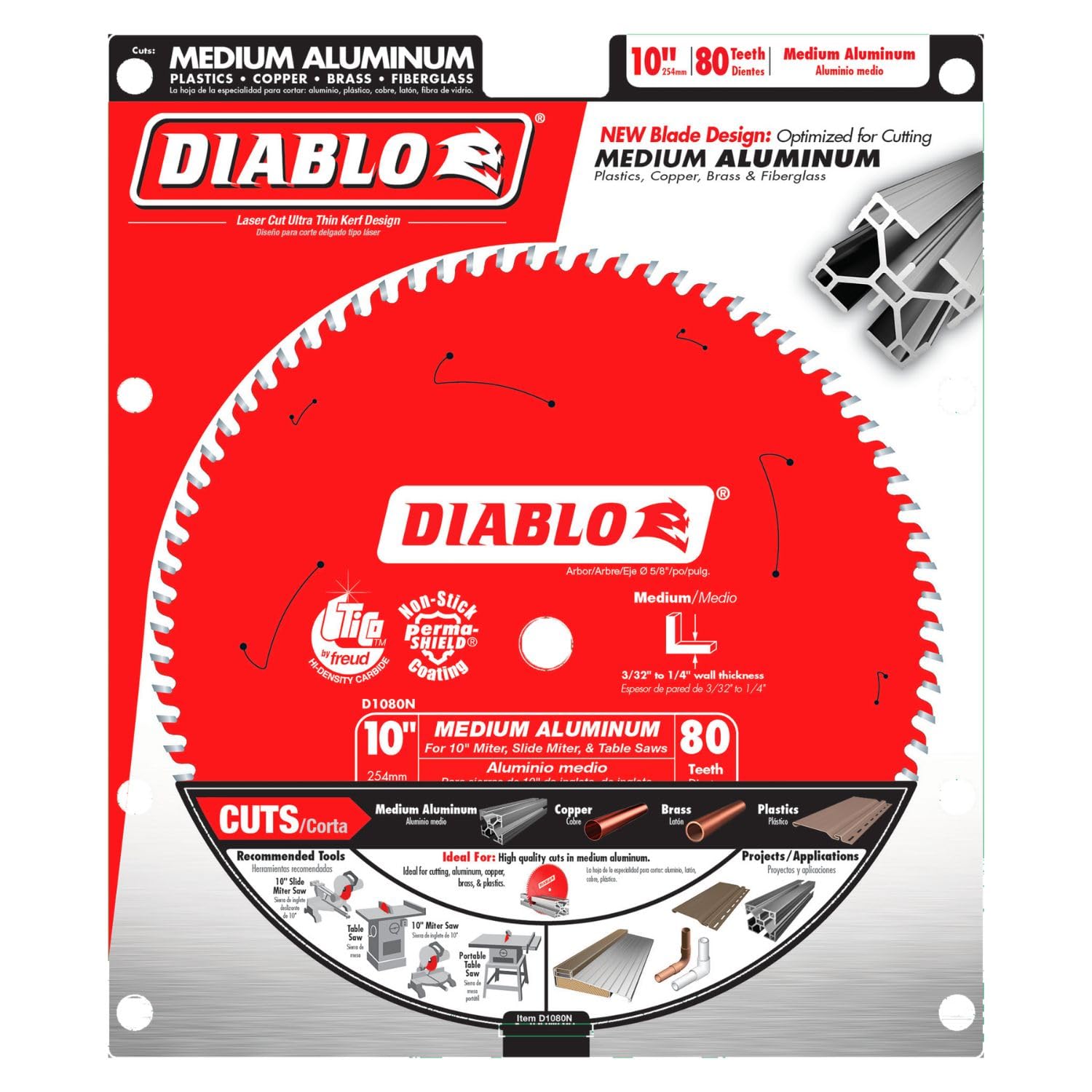

The Diablo 10" saw blade features 80 Triple Chip Grind teeth designed for burr-free cuts in aluminum and other metals. Its Tri-Metal Shock-Resistant Brazing and Perma-SHIELD coating provide exceptional durability and heat resistance, while laser-cut stabilizer vents reduce noise and vibration for precise, comfortable use. Engineered with TiCo Super-Density Micro-Grain Carbide, this blade offers extended cutting life and consistent performance up to 6000 RPM, making it ideal for professional remodeling, electrical, and plumbing applications.

| Material | Steel |

| Brand | Diablo |

| Product Dimensions | 10"L x 10"W |

| Color | Silver |

| Number of Teeth | 80 |

| Style | Circular |

| Item Weight | 1.5 Pounds |

| Compatible Material | Aluminum, Brass, Plastic, Metal, Copper |

| UPC | 008925020530 |

| Global Trade Identification Number | 00008925020530 |

| Manufacturer | Freud |

| Part Number | D1080N |

| Item Weight | 1.45 pounds |

| Item model number | D1080N |

| Is Discontinued By Manufacturer | No |

| Size | One Size |

| Power Source | Battery Powered |

| Item Package Quantity | 1 |

| Number Of Pieces | 1 |

| Cutting Diameter | 10 Inches |

| Measurement System | Metric |

| Included Components | Power Tool Accessories |

| Batteries Included? | No |

| Batteries Required? | No |

| Warranty Description | Limited lifetime |

| Assembled Diameter | 10 Inches |

P**L

Cutting edge!

Diablo really doesn't need a good review. It is in the, very few, top quality table saw blades. It is very accurate, cuts a sanding free, very smooth edge. I have always thrown away the blades that come with any tool and replace it with a Diablo blade. Top quality.

H**S

You can cut aluminum, but can you cut it square?

Its a good blade, however there is a definite learning curve trying to cut 3060 aluminum t-slot using basic woodworking equipment. The main challenge is trying to get a square and flat cut. I wasted several feet of aluminum before I found a system that worked for me.1. Use the most rigid saw you own. I first tried using a cheap 10" miter saw and could not get a square cut no matter what I tried. Eventually I gave up and just used the miter saw to break the extrusion down into rough sections that I moved to my table saw. My table saw is only a contractor saw but even so, it was orders of magnitude more rigid, and easier to adjust, than the miter saw.2. Always take the same size of "bite" out of the material. The saw and blade are going to flex, there is no way around it. So the question becomes compensating for that flex and always having the same amount of flex. By taking the same bite each time you can always have the same amount of deflection. I got the best result by taking exactly 1 saw blade width off the end of the extrusion. So to facilitate this I would use my miter saw to cut the extrusion 2 blade widths long, then bring to table saw and "shave" a saw blade width off each end to bring it to final length with nice clean square ends.3. You must clamp the extrusion during cutting. The blade pulls the extrusion back and forth as the alternating teeth hit the different parts of the extruded profile. If you dont have it clamped to the miter gauge, you end up with a cut that looks like a topographical map. Incredibly wavy.4. Use cutting wax and the same amount and application each time. Goes back to point 2 - trying to get a consistent amount of deflection. The wax really helps the cut but you need to make sure you are using the same amount and same application of wax so that the "ease" of cut is always the same and the deflection is always the same.5. Forget squaring your saw. Everything flexes so much that a squared blade won't produce a square cut. Instead just plan on sacrificing some extrusion with a trial-and-error setup. Make sure you are doing everything the same way you will do it for real (same material, same bite size, same lube, same clamp, etc). Then make a cut in alu extrusion. Check for square on the cut end of the extrusion. Tweak your saw a little and repeat until you are getting a good result on the extrusion. If you are shaving 1 saw blade width each time, it doesn't waste too much material.6. Wear eye protection for real. I am not a safety freak but you will be showered in hot aluminum chips and getting them into your eyes is not fun.Anyway... great blade, works well for cutting alu extrusion. Just use a cutting wax and figure out how to compensate for the deflection in your saw and you will have success. And if you thought sawdust was "man glitter"... you gonna learn today.

N**K

Quality blade

Bought it for a table saw specifically to cut acrylic panels. Worked perfectly, even with thin ones. Money well spent. I recommend this blade.

A**C

Outstanding Quality and Cutting Capability

I recommend these.

L**N

Cuts Aluminium beautifully

This is my second review of Freud saw blades and this one I like whereas the other one was crap. I had to cut some aluminium plate, not much but I thought the correct blade would be worth investing in since I was making new inserts for my table saw and accuracy was important to me. All my tools are for home use so can't verify if they will last as I don't do enough work with them to wear them out. It cut the 1/8" aluminium plate on my table saw and left a nice smooth cut. I only make a bit of furniture or other household items for personal use so none of my tools have hard life. I need to cut a little bit of aluminium and on rare occasions some plexiglass for making machine guards. I must say the saw blade worked very well on both materials gave nice smooth cuts with no chips on either material.

T**I

Cuts ABS plastic panel like a knife through butter

I have recently been building robot chassis out of 1/4 inch thick ABS plastic panels and found that the old 180 tooth narrow saw blade that I had been using had given up the ghost. So after looking around locally, I decided on this saw blade as it was reasonably priced and had received reasonable reviews both here and on Home Depot.After installing the saw blade on my table saw, I found that I was getting excellent cuts without the plastic jamming the saw blade which cuts the ABS like a knife though butter.

J**N

great in cutting acrylic

I mount it on my 10" table saw to cut 1/4" acrylic and it works fine. Although it can still melt the acrylic but just a little on the edge sometimes which can be easily removed with your finger, so I give it a 4. I've used it many times and I am very happy that I bought it. The cut is smooth and precise. I havn't tried any other blade that can do better without melting. Freud has a different and supposedly better blade for cutting acrylic, but it costs a lot more.

M**E

Excellent blade for acrylic

I own other Diablo brand blades and they cut excellent for my needs. I like to have nice equipment for home projects, hobbies, This blade was bought for some acrylic projects I have. Cut the 1/4” material perfect. Very smooth, very clean cuts on my Dewalt table saw. Very happy overall. Shipping was fast, blade was as advertised, came in original packaging and in mint condition.

Trustpilot

2 months ago

1 week ago